Key Takeaways:

-

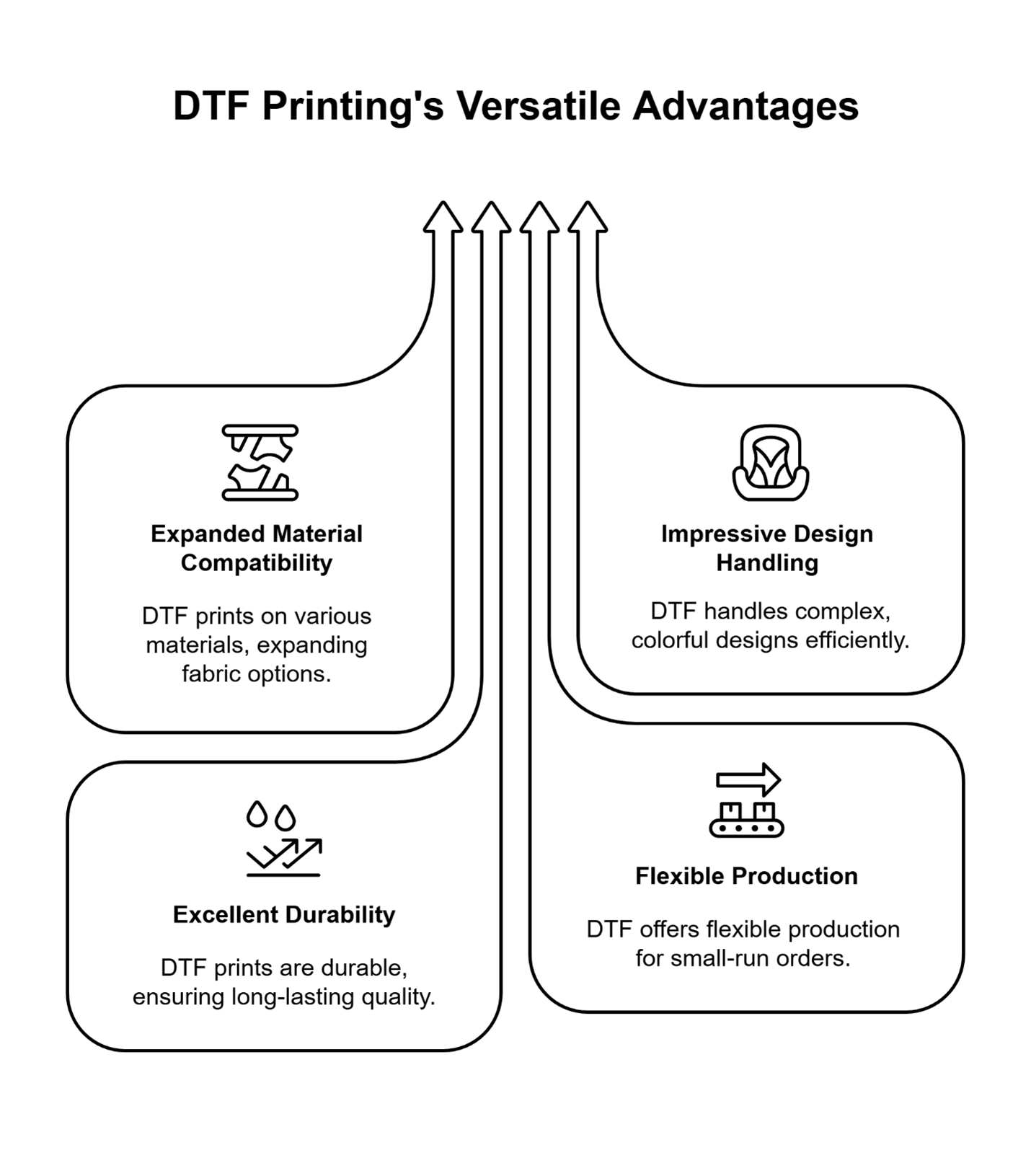

Multi-Material Compatibility: DTF printing works effectively on cotton, synthetics like polyester and nylon, blended fabrics, and even specialty materials like leather and canvas with proper testing, expanding what businesses can offer clients.

-

Design Complexity Without Cost Penalties: Unlike traditional methods where each color adds setup costs, DTF handles complex multi-color designs, fine details, and smooth gradients at the same production cost regardless of color count.

-

Durability and Comfort Balance: Properly applied DTF prints typically survive 30+ wash cycles with minimal degradation while providing a "moderate hand" that balances softness with durability and offers reasonable stretch capability.

- Production Workflow Advantages: DTF makes small batch production (under 24-36 pieces) economically viable, allows multiple design placements without registration issues, and separates printing from application for efficient workflow management.

DTF printing offers apparel businesses a way to accept previously challenging customization requests while maintaining quality, efficiency, and customer satisfaction through expanded material options and production flexibility.

Facing more complex customization requests lately? You're not alone.

When traditional printing methods leave you turning away business or settling for mediocre design quality, it's time to explore alternatives. Direct to Film (DTF) printing might just be the solution you've been searching for.

Let's dive into how DTF printing could revolutionize your apparel business's customization capabilities. We'll explore everything from material versatility to design reproduction and production workflows that can help you meet even the most demanding client requests.

The DTF Difference: How It Actually Works

Ever wonder what makes DTF unique? At its core, DTF creates transfers through a distinctive process.

Your designs get printed onto specialized film using water-based inks, layered with white backing, then applied to garments with adhesive powder and heat. Simple enough, right? But here's where it gets interesting.

Unlike other methods, DTF printing works in two distinct phases. First, you print to film. Then, you apply the complete design to the garment in one heat press application. This two-step approach creates a fundamentally different workflow for your production floor.

No more aligning multiple screens for complex designs with lots of colors! The white underbase layer is crucial. Think of it as the foundation that prevents dark fabric colors from showing through your design.

The result? Vibrant, opaque colors that pop on virtually any color garment. When applied correctly, these transfers deliver stunning color vibrancy comparable to traditional methods but without the headaches for intricate designs.

+-------------------------------------------------------------------------------------------------------+

💡 Quick Takeaways

-

Technical Process: The film-based transfer method creates a two-phase workflow that separates printing from application.

-

Streamlined Transfer: Designs transfer in a single heat application step, eliminating complex multi-screen alignment issues.

- Color Foundation: The white underbase provides exceptional opacity for vibrant designs on dark fabrics.

+-------------------------------------------------------------------------------------------------------+

Breaking Material Barriers: Fabric Compatibility That Expands Your Offerings

Material limitations frustrate even the most patient business owners. Turning away customers because their jacket fabric won't work with your current printing method? That stops now.

Cotton? Absolutely. Natural fibers take DTF transfers beautifully, with excellent adhesion and color vibrancy when properly cured. But that's just the beginning.

Synthetics like polyester, nylon, and performance fabrics? Yes to those too. While other methods struggle with these materials or require specific fiber compositions, DTF handles them with impressive results.

Blended fabrics also show excellent adhesion when you dial in the right application parameters. The real game-changer? Specialty materials. Leather, canvas, and other surfaces that would normally send you running for specialized equipment often accept DTF transfers after some testing and adjustment.

Each material responds differently, of course. The depth of texture, material composition, and your application technique all play crucial roles in the final result. Some textured fabrics that would cause nightmares with other printing methods actually work surprisingly well with DTF.

The heat-applied transfer can sometimes bridge slight textures that would otherwise be problematic. But remember – always test new materials before promising results to clients!

+-------------------------------------------------------------------------------------------------------+

💡 Quick Takeaways

-

Expanded Material Range: Works beautifully with natural fibers like cotton while handling synthetics that challenge other methods.

-

Specialty Surface Potential: With proper testing, materials like leather and canvas might finally be viable options for your business.

- Texture Tolerance: The heat application process can sometimes accommodate textured surfaces better than methods requiring flat, smooth substrates.

+-------------------------------------------------------------------------------------------------------+

Bringing Complex Designs to Life: Detail Reproduction That Impresses

"Sorry, we can't print that." How many times have you said those words to a client with a complex design request?

Direct to Film printing could change that conversation entirely. Color reproduction capabilities vary by system, but most modern DTF setups use CMYK+White process colors that produce an impressive color range.

Need to match specific brand colors? You'll still need calibration and testing, but the potential is there. The real advantage emerges with complex, multi-color designs.

No more cost prohibitions for detailed, vibrant artwork in small quantities. A design with 10 colors costs the same to produce as one with just two – a dramatic departure from methods that require separate setup for each color.

Detail reproduction? Exceptional. Fine lines, small text, and photographic elements transfer with remarkable fidelity. While extremely tiny text (below 6-point) might still cause issues, most detailed elements reproduce beautifully.

The level of detail won't necessarily match the absolute highest-end systems on the market, but it surpasses many traditional methods by a significant margin.

Gradients and transparency effects? They'll make you smile. The smooth transitions and subtle effects that often cause headaches with other techniques translate beautifully through DTF printing.

No more blocky halftones ruining your smooth color transitions. The quality depends on your specific equipment and settings, of course, but the potential for stunning gradient reproduction exists right out of the gate.

+-------------------------------------------------------------------------------------------------------+

💡 Quick Takeaways

- Color Freedom: Reproduce full-color designs without incurring per-color cost increases, opening new creative possibilities.

- Detail Preservation: Transfer intricate designs with impressive fidelity, though extremely small elements still require attention.

- Smooth Transitions: Achieve gradient effects and transparency without the blocky appearance that plagues some other methods.

+-------------------------------------------------------------------------------------------------------+

Beyond the Sale: Print Durability and Feel That Keep Customers Coming Back

Let's talk about what happens after the sale. Print longevity and how the design feels against the skin matter tremendously to end-users – and directly impact repeat business.

Wash test results tell an impressive story. Properly applied DTF prints typically survive 30+ wash cycles with minimal degradation. No significant cracking or fading when you use quality materials and nail the application technique.

This outstanding durability protects both your reputation and your clients' brand representation on merchandise they sell or distribute. The feel of the print? That sweet spot between durability and comfort.

DTF creates what industry pros call a "moderate hand" – substantially softer and more flexible than traditional plastisol prints that can sometimes feel like a stiff plastic layer on garments.

While not completely undetectable like some premium methods on perfect substrates, the smooth surface resists cracking when stretched, enhancing both comfort and longevity.

For athletic or fitted garments, stretch matters enormously. DTF delivers moderate stretch capability that allows designs to flex with the garment without immediate cracking.

This makes it suitable for many performance garments where some elasticity is expected. Though extreme stretch applications might still present challenges, most standard stretch requirements perform beautifully.

+-------------------------------------------------------------------------------------------------------+

💡 Quick Takeaways

- Exceptional Durability: Properly applied prints typically maintain integrity through a 30+ wash cycles, preserving both appearance and customer satisfaction.

- Balanced Feel: Achieves a middle-ground hand that balances softness with durability, creating comfortable wearable products.

- Flexible Performance: The moderate stretch capability supports application on performance garments better than rigid print methods.

+-------------------------------------------------------------------------------------------------------+

Production Workflow Advantages: Meeting Diverse Client Demands

The practical production benefits might be the most compelling reason to consider DTF for your business. Small batch production finally makes economic sense.

Traditional methods become prohibitively expensive for limited quantity orders due to setup costs, while DTF requires no such per-design investment. Most shops find DTF printing cost-effective for runs under 24-36 pieces, though economic factors vary based on your specific equipment and workflow.

Small orders no longer need to be money-losers. Want to offer multiple placement options? No problem. DTF transfers can be applied to various garment positions with relative ease.

Each placement requires separate handling and positioning, but without the registration nightmares of other techniques. This versatility helps fulfill requests for comprehensive customization with designs on sleeves, backs, fronts, and more.

The separation between printing and application creates fascinating workflow possibilities. You can produce transfers in batches completely independent from the heat application process.

This separation enables parallel processing and inventory building of common designs. For businesses with recurring designs or flash sales, this could revolutionize your production planning.

+-------------------------------------------------------------------------------------------------------+

💡 Quick Takeaways

- Small-Run Viability: Eliminates prohibitive setup costs that make small runs unprofitable with some other methods.

- Design Placement Freedom: Apply multiple designs to different garment locations without complex registration challenges.

- Production Flexibility: Separate printing from application to create workflow advantages and inventory options for recurring designs.

+-------------------------------------------------------------------------------------------------------+

Bringing It All Together

DTF printing offers a compelling package of capabilities that could help you say "yes" to projects you're currently declining. The expanded material compatibility, impressive design handling, excellent durability, and flexible production advantages create opportunities to tackle previously challenging requests while maintaining quality and efficiency.

Take some time to evaluate how these capabilities might address specific limitations you currently face. Could your business benefit from expanded fabric options? Are complex, colorful designs currently causing production bottlenecks? Do small-run orders make you cringe because of setup costs?

A thoughtful assessment of your client requests, current constraints, and market positioning will help you determine if DTF printing deserves a place in your production arsenal.

Frequently Asked Questions

Q: How does implementing DTF printing affect overall production workflow efficiency?

A: DTF transforms workflow dynamics by separating design preparation and printing from heat application. This split creates flexibility many shops desperately need.

You might print transfers all morning, then apply them across various garments in the afternoon. Or build an inventory of common designs ready for immediate application when orders arrive.

Success hinges on thoughtful production scheduling and proper staff training. Most businesses need at least a few weeks to optimize their workflow after implementation.

Q: What cross-functional impacts should I expect when adding DTF capabilities?

A: Beyond the production floor, DTF touches nearly every department. Your sales team needs thorough education on capabilities to avoid overpromising or underutilizing the technology.

Design staff must understand file preparation requirements that might differ from your current methods. Customer service requires clear guidelines about appropriate applications to set realistic client expectations.

Plan for comprehensive cross-departmental training and create clear documentation to ensure everyone understands the possibilities and limitations.

Q: How does DTF print durability influence client satisfaction?

A: Print durability directly impacts repeat business - period. When discussing DTF with clients, set clear expectations about the typical 30+ wash cycle durability.

Many shops find that showing wash test samples dramatically helps clients understand the longevity advantage. This becomes particularly important when clients have previously experienced premature failure with other decoration techniques.

The durability story often becomes a key selling point that justifies premium pricing for quality-conscious clients.

Frequently Unasked Questions

Q: How might expanding DTF customization capabilities impact your pricing strategy?

A: Enhanced customization often creates opportunities for strategic price tiering. Consider developing capability-based pricing structures that reflect both production costs and perceived market value.

Some businesses successfully create premium options for complex designs or special materials that wouldn't be possible without DTF. Others focus on the small-quantity efficiency to capture orders they previously declined.

The shops that succeed most dramatically take time to analyze the true value proposition of their expanded capabilities rather than simply applying standard markup formulas.

Q: What operational dependencies could affect your DTF implementation?

A: Look beyond the printer itself when planning implementation. Design intake procedures may need modification to capture specific requirements. Quality control systems should address evaluation criteria appropriate for this method.

Inventory management must accommodate transfer film and specialized supplies. Even shipping processes might need adjustment for certain products.

Successful implementation typically requires a comprehensive operational review from order intake to delivery.

Q: How could the feel and durability of DTF prints influence your product positioning?

A: The balanced hand and excellent durability of DTF prints create interesting positioning opportunities. Some shops successfully create tiered product lines where DTF occupies a mid-premium position, offering better durability than economy methods while providing more design flexibility than premium alternatives.

Others emphasize the comfort advantage compared to traditional transfers when marketing to clients focused on wearability. Consider how these characteristics might help differentiate your offerings in an increasingly competitive market.

Disclaimer: This content is for informational purposes only and not intended as business advice. No business relationship is formed through this content. The information provided does not replace professional consultation. Please consult qualified business advisors for guidance specific to your organization's situation.

Unlock Limitless Customization — Without Compromise

At Best Price DTF, we know that meeting diverse client demands takes more than just good design — it takes the right tools. With our advanced DTF transfer solutions, you can say yes to more complex requests, handle a wider range of materials, and deliver stunning, full-color designs that last. Whether you're producing small batches or scaling up, our DTF sheets and gang sheets are built to keep your workflow efficient and your results exceptional.

👉 Ready to expand what’s possible? Contact us today and let’s talk about how our DTF printing services can help transform your customization capabilities.

🚚 Bonus: Enjoy Free Shipping on transfers $99+ — because great prints shouldn’t come with hidden costs.

👕 Want inspiration for your next print run?

Follow us on Instagram, Facebook, and YouTube for real-world results, tips, and updates from the Best Price DTF team.

Let’s create something bold — and built to last.